COVID Cart

Acceleration Through Recycling

Accomplished through the UMass Amherst Technical Theater Department

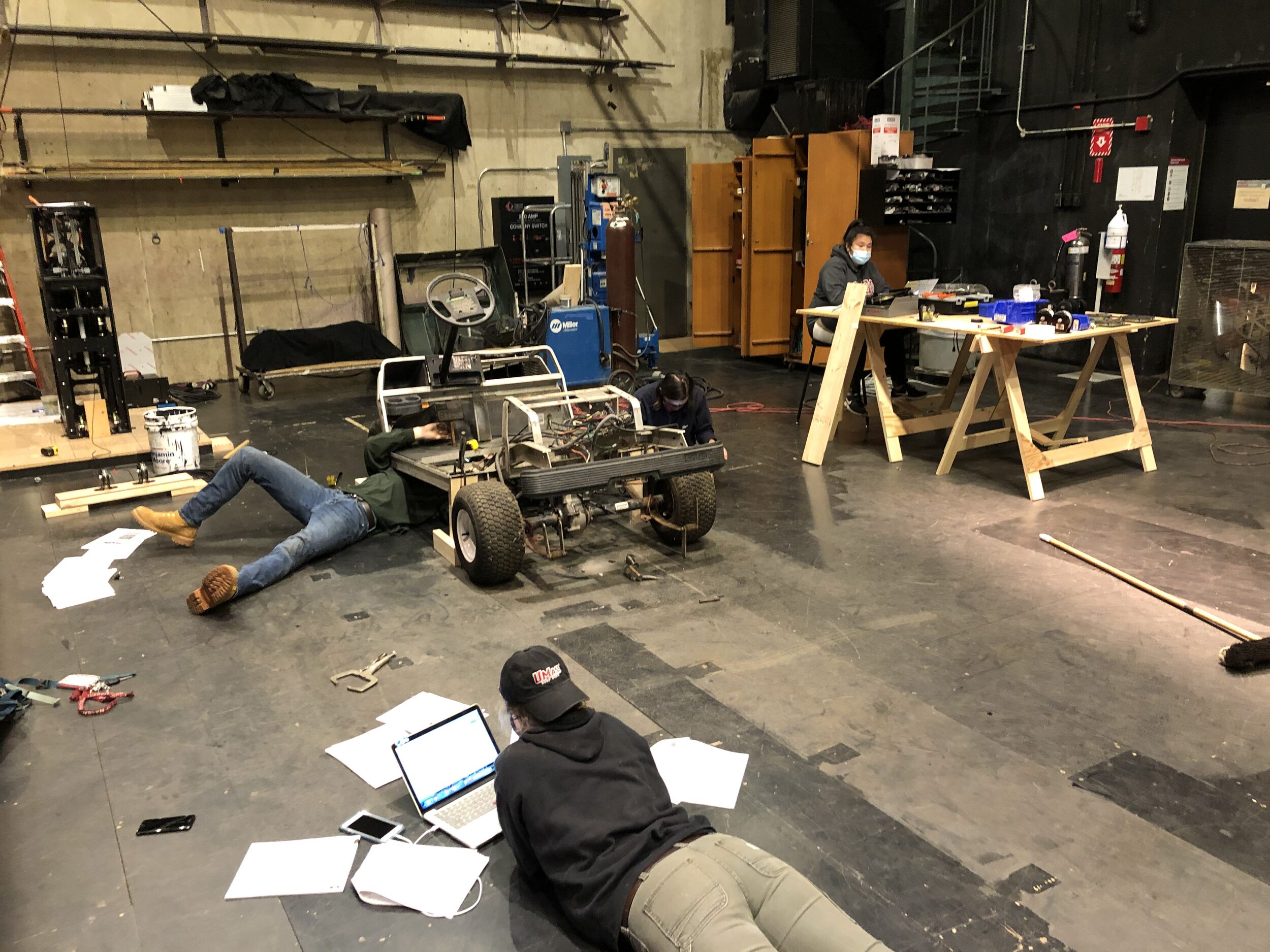

In the Fall semester of 2020, I procured a free salvage electric golf cart from a local rental company. The cart had no batteries, no ignition system, and was a mess of jumped connections, spliced wires, and broken components. The goal was to create a modular, working cart, with a modular frame that could have modular and removable attachments.

The team was split into several parts: designers, mechanical technicians, and one electrical technician - myself. With some mentorship and help from our in-house electrician, over the course of the following two semesters, I repaired the entire electrical system of the cart.

Repairing the cart included:

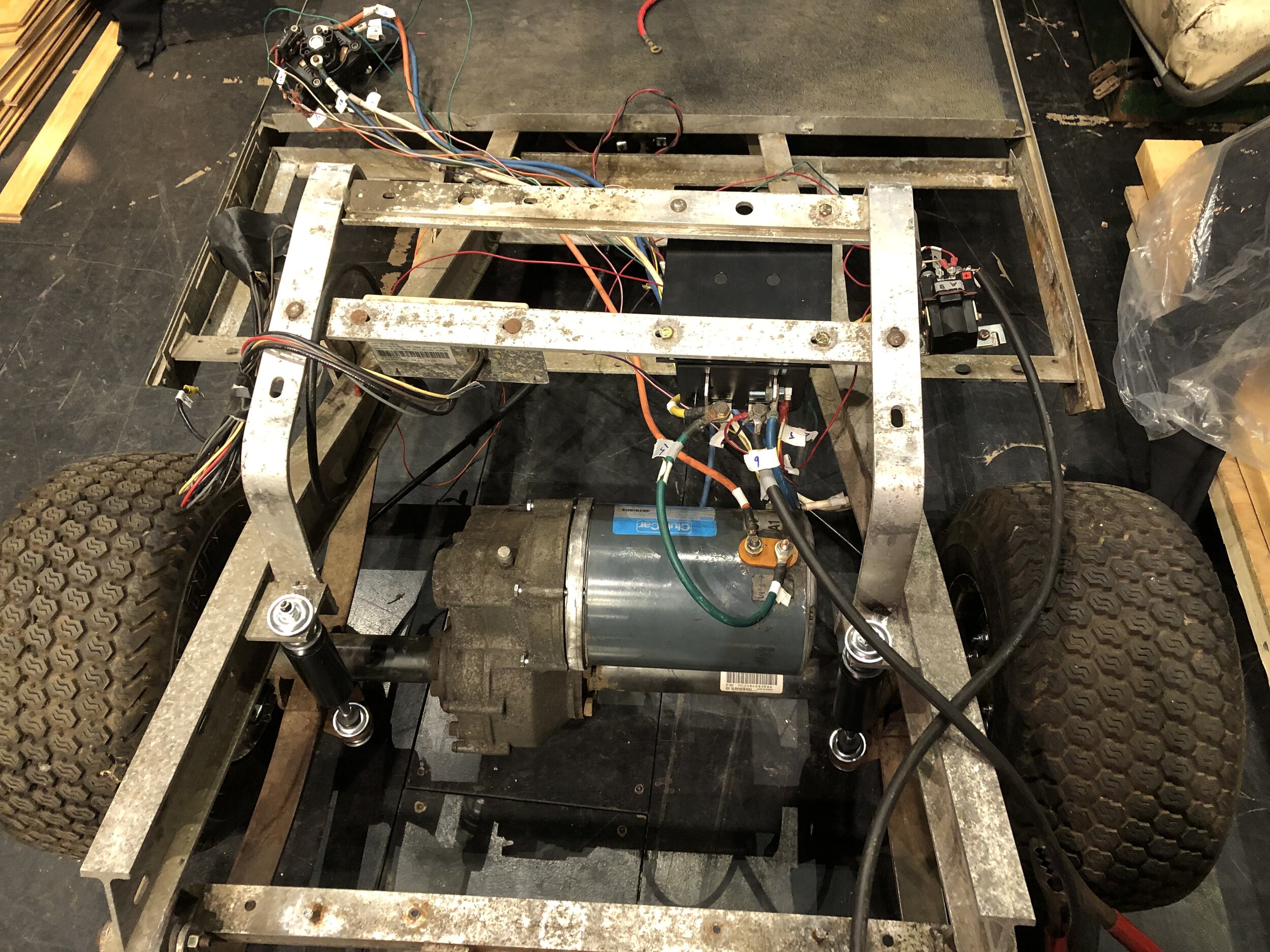

Removingepairing broken connections inside the DC motor.

Replacing faulty wires and connections.

Testing switches and components, replacing unusable ones and salvaging ones that could be operational.

Completely reworking the wiring to create a functional cart system, made up of modern and old parts.

Wiring four salvaged car batteries, instead of expensive modern golf cart batteries, to operate as power.

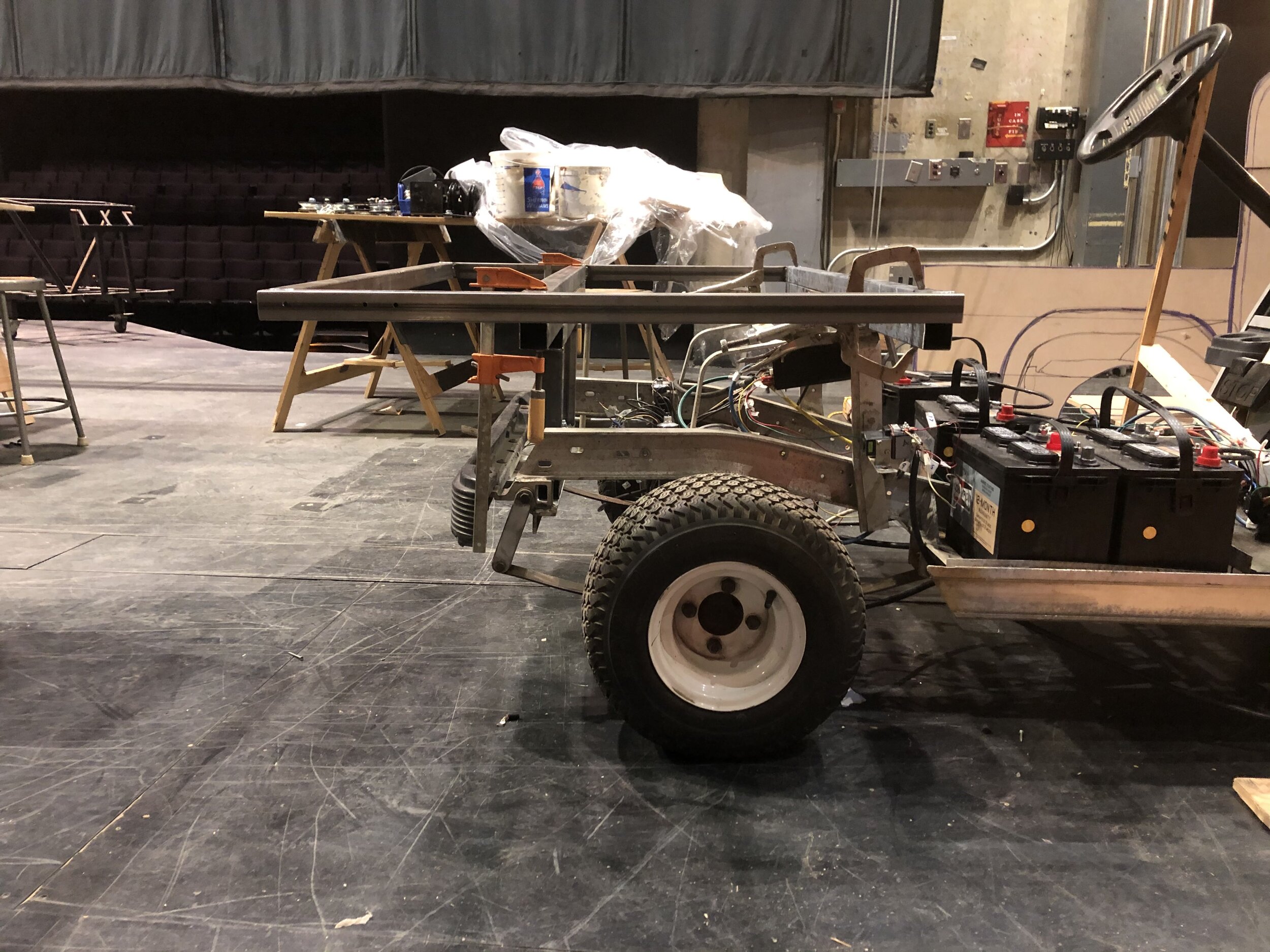

As someone without an extensive electrical background, this was a big challenge. The technical diagrams were poorly laid out and confusing, the existing wiring was clearly faulty and incorrectly installed, and it was incredibly difficult to figure out what parts were actually functional due to the age of the equipment - this cart was from 1995, and had clearly been through a lot. In addition, this project was undertaken while observing social distancing and mask mandates during both semesters before the COVID-19 vaccine was widely available, and while the virus was raging through the campus population. Despite these many difficulties, we were able to accomplish this project without any cases of infection. And, at the end of the project, not only did we have a functional cart, but we were even able to install a small truck bed on it, plus a new modular frame. It is fully functional, runs faster than the original top speed, and is used to move people and materials from the theater shop to anywhere across campus

Environmental Considerations

A big inspiration, and hurdle, for this project was sustainability. At every step of the way, the technical shop professor and leader, Michael Cottom, asked the same question: “How do we keep this green?” From the very start, we wanted to find a salvage vehicle not only due to our extremely limited budget, but to refurbish an existing product rather than purchase a new one. This project also would have been much easier working with a gas powered golf cart, there are far fewer components to fix, and hardly any wiring to work with. But using an electric cart was far more sustainable. Currently, the cart recharges off of a trickle-charge car battery charger, but there are plans to convert either the charger to solar, or connect the cart directly to a solar panel. This project gave me a whole new perspective on how making something truly sustainable is a lot more work, but far more rewarding in the end.